Bridge Bearings can be introduced in the following aspects: Categories: 1. Rubber pad bearing (GYZ)

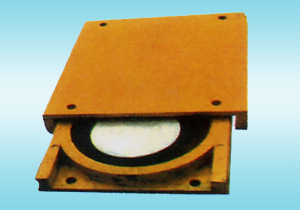

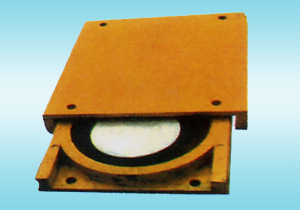

2. Pot bearing (GPZ )

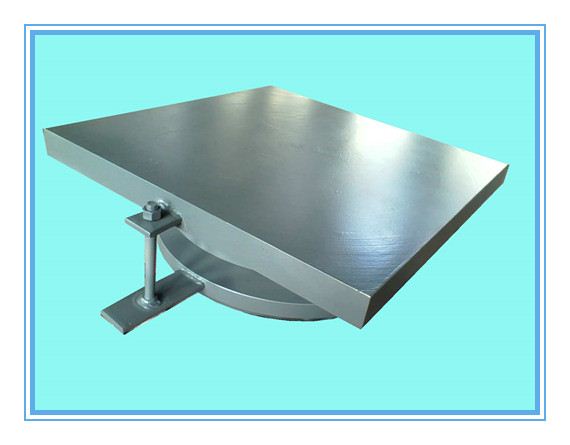

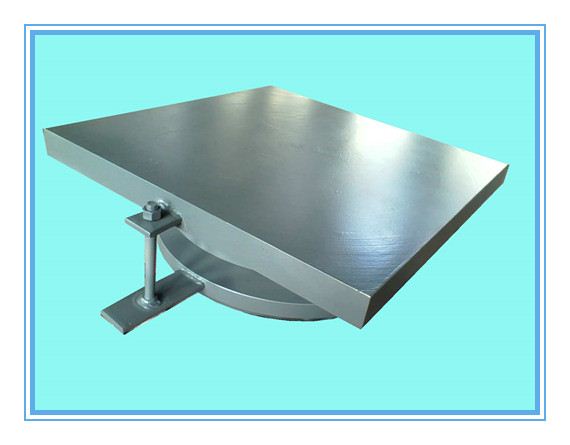

3. Spherical bearing (LQZ)

Description

DescriptionBridge bearings and expansion joint are important parts of whole bridge components, but the amount money that spent on bridge bearing and expansion joint is only 2-3.5%, it is absolutely a wise choice to evaluate it within the whole project to prevent unnecessary costs.

Description of bridge rubber pad bearingsIt is made from multilayers of rubber sheets and steel plates, by high temperature vulcanization bonding. It has enough vertical stiffness, and can transfer the counter-force of superstructure to abutment. It has good elasticity for beam end rotation, and better shear deformation for horizontal displacement of superstructures

Shape and size

Rectangular--100x100x14mm to 700x700x200mm in common, or can be customized

Round --100mm to 1000mm in common, or can be customized

Description of pot bearings: 1.The basic elements of a pot bearing consists of a shallow cylinder, known as pot, an elastomeric pad known as disc, a single or set of sealing rings, piston and sliding surfaces. Masonry plates and base plates are common for the installation of pot bearings, as they allow attachment of the bearings and increase the support area on the pier and abutment. Pot bearings are fixed against all translation unless they are used with a PTFE sliding surface.

2.Pot rubber bearing is used to semi closed steel in pelvic cavity of the elastic rubber block, in three to the stress state has the characteristics of fluid to achieve the rotation of the upper part of the bridge, also rely on steel plate in the center of the F4 board and the upper seat plate of stainless steel plate between the low friction coefficient to realize the horizontal displacement of the upper structure, bearing to withstand the shear no longer by the rubber completely bear, and indirect effects on the steel bottom slip between the pot and F4 board and so on.This series bearing capacity is 31 levels, bearing capacity 0.8MN-60MN, can meet the needs of large-scale construction of the bridge.

Description of spherical bearings: Spherical bearing is reliable in force transmission and flexible in rotation. it possesses the capacity of the pot bearing but superior than the pot bearing in many aspects. Allowable in bearing displacement and adaptable in supporting angles.

ApplicationRubber pad bearingRubber pad bearings are designed for use in bridge and building construction - under pre-cast concrete beams, steel beam supports and other support points - as local load carrying components. Rubber bearings are flexible support points used in the construction of viaducts and bridges.

Pot bearing The product has been successfully used in a broad range of applications which include: bridges, viaducts, high rise buildings, stadiums and dams.

Spherical bearingSpherical bearing with sliding spherical PTFE plate achieve the support of turning process. The rotational torque is only related to the friction coefficient of the spherical bearing and radius of spherical. It has nothing to do with the rotating angle of bearing size. Therefore, it is especially applicable to the rotation angle, the design angle up to 0.05 rad.

The rotation performance of the bearings is consistent, which is also suitable for wide bridge and curved bridge.

Features

Rubber pad bearings are made of multiple layers of rubber sandwiched with and bound to thin steel sheets, and then through vulcanization.

Its vertical rigidity is sufficient to bear the perpendicular load and to shift the pressure reliably from the superstructure to the piers.

Its elasticity is high enough to suit the rotation of the beam end. Its shear deformation is sufficient to cope with the horizontal displacement of the superstructure.

Pot rubber bridge bearings have been designed to be very easy to install, maintenance-free and cost-effective.Bridge pot bearings are designed for very high vertical, horizontal and lateral loads where rotational structural displacements need to be accommodated.

The pot rubber bearings have an advantage of large horizontal displacement, flexible rotation, light weight, compact structure, simple structure, low construction height, convenient processing and manufacture, saving steel, reducing the cost and so on. It is suitable to be applied to large bridge.

Spherical bearings transfer force through spherical face,and the reacting force in the concrete is relatively uniform, which is helpful to avoid necking phenomenon

Without rubber bearing pressure, there is no effect on the performance of rubber aging rotating bearings, especially with the low temperature area.

Technical data

Technical data of rubber pad bearing

| Standard |

JT/T4-2004 |

BS5400 Section 9.2 |

| Rubber |

Natural Rubber |

Neoprene

CR

|

Natural

Rubber

|

Neoprene

CR

|

| Hardness(IRHD) |

60±5 |

60±5 |

50±5/60±5/70±5 |

Tensile Strength (M Pa)≥

|

18 |

17 |

17 |

15.5 |

Ultimate Elongation (%)≥

|

450 |

400 |

450/400/350 |

400/350/300 |

| Compression Set |

70 o C×22h |

70 o C×22h |

100 o C×22h |

| |

<30 |

<15 |

<30 |

<35 |

| Heat Resistance |

Test Condition |

70 o C×168h |

100 o C×70h |

70 o C×168h |

100 o C×48h |

| |

Change in Hardness |

-5,+10 |

0,+10 |

<10 |

<15 |

| |

(IRHD) |

|

|

|

|

| |

Rate of Tensile Strength Reduction(%) |

<15 |

<15 |

| |

Rate of Ultimate |

<20 |

<40 |

<20 |

<40 |

| |

Elongation Reduction |

|

|

|

|

| |

(%) |

|

|

|

|

| Ozone Resistance |

25~50pphm,20% strain |

25~50pphm,20% strain |

| |

40 o C×96h |

30 o C×96h |

| |

No Cracks |

No Cracks |

(a) Two way moveable bearing has vertical rotation,longitudinal and horizontal gliding performances and its serial number is SX;

(b) One-way movable bearing has vertical rotation and one-way gliding performances and its serial number is DX;

(c) Fixed bearing: only has vertical rotation performance and its serial number is GD.

| Types of Bearing Counterforce Type |

Maximum displacement in direction longitudinal the bridge(mm) |

Maximum displacement in transversal direction(mm) |

| GD |

SX |

DX |

GD |

SX |

DX |

| 1000-3000 |

0 |

±50,±100 |

±50,±100 |

0 |

±5,±10 |

0 |

| 3500-9000 |

0 |

±100,±150 |

±100,±150 |

0 |

±10,±15 |

0 |

| 10000-30000 |

0 |

±150,±200 |

±150,±200 |

0 |

±15,±20 |

0 |

1. The rotation angle of the support is divided into 0.01,0.05 and 0.02rad, which can be increased according to the requirement.

2. The vertical bearing capacity of 1000-200000KN is divided into 16 levels, and the bearing capacity of the bearing is 10%.

3. Coefficient of friction: Normal temperature type μ≤0.03; Hardy type μ≤0.05.

4. Displacement of bearing design:

a.bridge in axial direction: ±50, ±100, ±150mm

b.transverse direction of bridge: ±20mm

The design displacement can also be changed according to the engineering requirements.

Company Profile

Company Profile