Negotiable

The date of payment from buyers deliver within days

Shandong

Long-term effective

2017-11-29 11:10

242

Company Profile

Company Profile

By certification [File Integrity]

Contact:Ms. Jennifer Lee(Mr.)

Email:

Telephone:

Phone:

Area:Shandong

Address:Shandong

Website: http://qdxinghe.jssytm.com/

Material: iron, FCD400 FCD450 FCD 500 FCD600 FCD700

Technology: sand casting, iron casting

Surface treatment: sand blast, polishing, painting, powder coating

Machining: grinding, tapping, drilling, cnc

Application: engineering machinery parts, agricultural casting, motor housing

2.sand casting flow chart:

prepare drawing--check drawing--design mould--mechanical molding--melting and pouring--cooling--sand removal--grinding--sand blast as follow:

Qingdao Xinghe Machinery Co.,Ltd.

| PROCESS | MATERIAL | STANDARD | |

| SAND CASTING |

Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM BS JIS DIN etc |

| Furan Resin Sand | |||

| Cold Harden Resin Sand | |||

| INVESTMENT CASTING |

Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum | |

| Silica Sol | |||

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum | |

| Die Forging | |||

| Roll Forging | |||

| STAMPING MACHINING | STAMPING MACHINING | All metal material | |

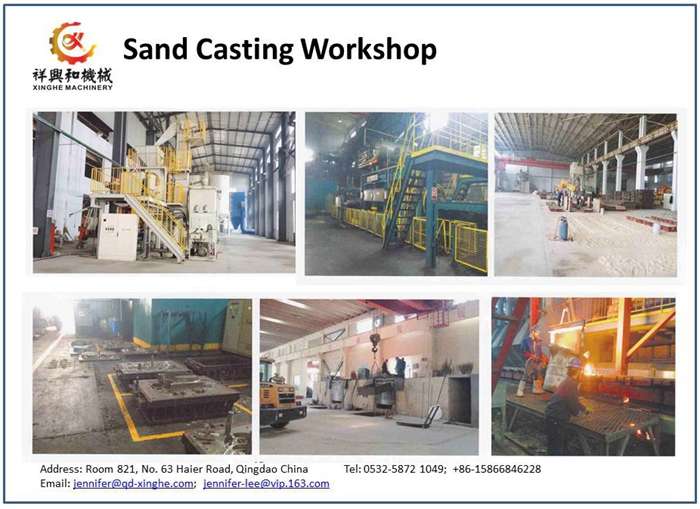

Sand casting:

Plant has large-scale casting equipment of 50 sets, we have different technology with different type of sand kind and parts shape. The largest casting we can cast is 15 tons. Our yearly capacity for sand casting is about 2000 tons for cast steel and 30000 tons for cast iron.

Inspection process:

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

Package:

1.) wooden, carton;

2.) pallet;

3.) as customers' requirement.

1) Experience in casting for many years and served customers all around the world.

2) International advanced-level equipment such as CNC, numerical lathes, CMM.

3) OEM service, you demand is our pursued.

4) ISO quality control

Please send us information for quote: drawing, material, weight, quantity and request.

Yes, we make the drawing of your sample and duplicate the sample.

Sample: 25-30 days after you start to make mold. The accurate time depends on your product.

Order time: 35-40 days after the payment. The accurate time depends on your product.

Tooling: 100% TT advanced.

Main order: 50% deposit, balance 50% to be paid before shipment.

PDF, ISGS, DWG, STEP, MAX..

We can't offer you all the information of our customer because we have duty to protect our customers' privacy. But we can provide you some part of B/L.

Contact us: